Projects

Structural Testing

Testing of Concrete Columns After Repair of Minor Damage by Injection of Epoxy Resin

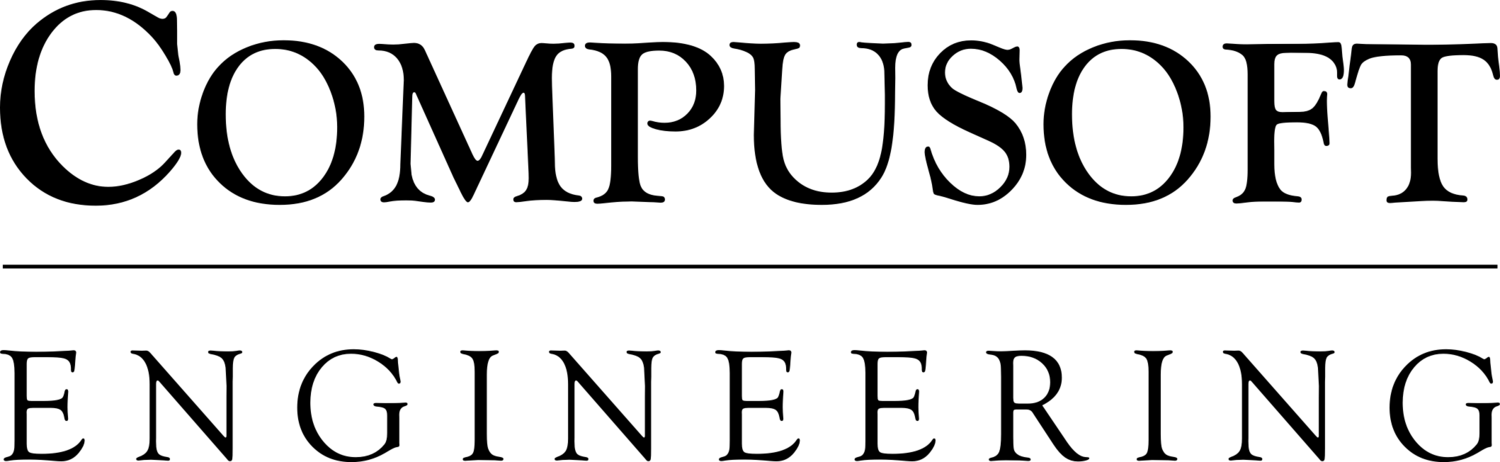

Compusoft Engineering were engaged to develop and implement an experimental programme to investigate the performance of reinforced concrete columns following repair of minor earthquake damage by epoxy injection.

Replicas of columns from a 1970s building were painstakingly constructed before being tested at the University of Auckland structural laboratory. One column was tested directly until failure occurred, while the second was repaired using epoxy injection after minor damage had occurred and then retested until failure occurred. As expected, the behaviour of both columns was controlled by degradation of lap splices at their base.

Results of the testing showed that the behaviour of the repaired column was similar to the column that was tested directly to failure. While the repaired specimen had somewhat lower stiffness, it was stiffer than would be estimated using relevant assessment guidance.

Further details can be found in the following paper:

Brooke, N. J., and Davidson, B. J. (2022). “Experimental Investigation of the Performance of Concrete Columns After Repair of Minor Damage by Injection of Epoxy Resin.” SESOC Journal, 35(2), pp.38–53.

Seismic Cyclic Testing, Clarendon House, Christchurch, New Zealand

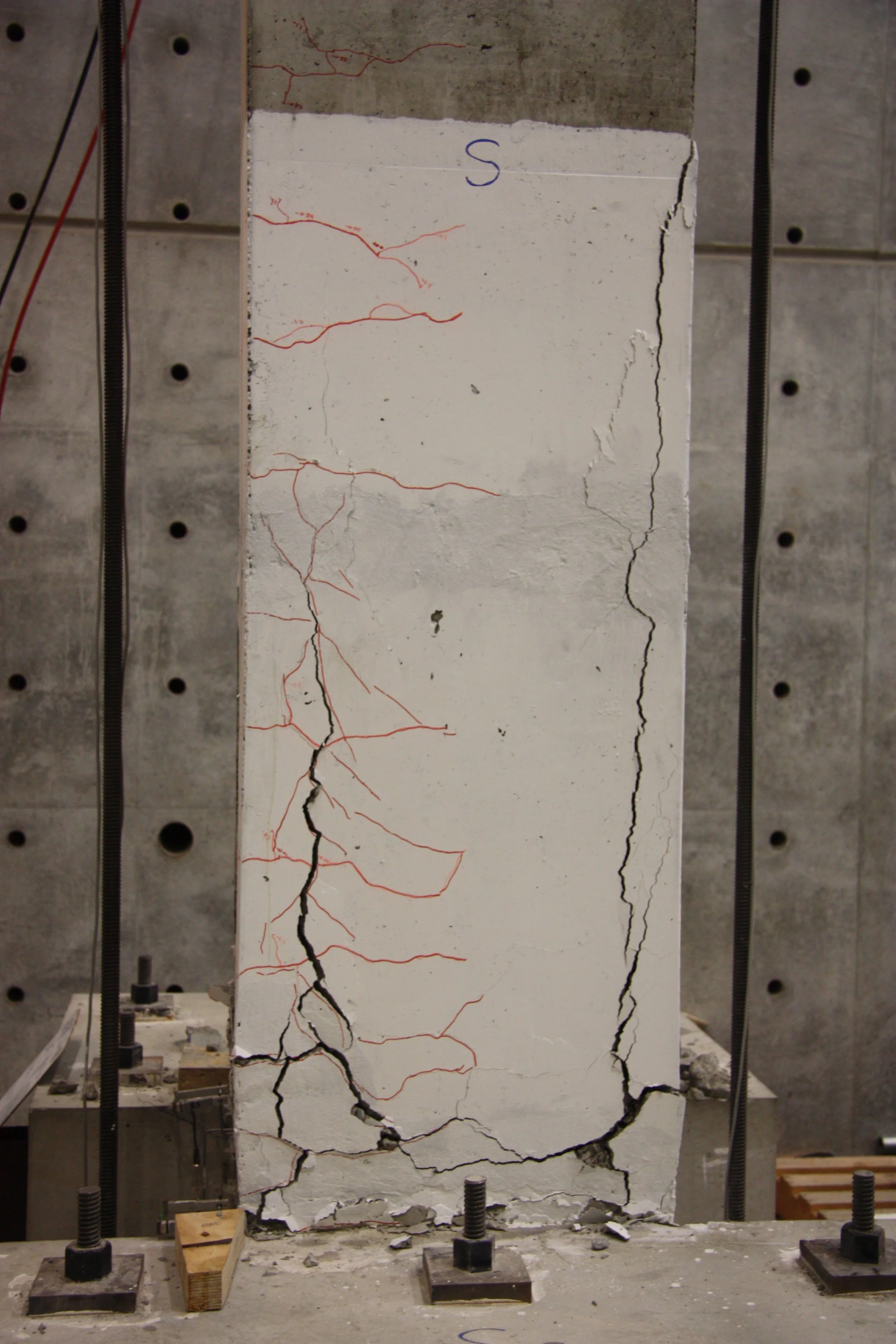

Compusoft Engineering were engaged to 'test two

H-frame reinforced concrete (RC) components extracted from the Clarendon Tower in Christchurch.

The Clarendon Tower was constructed in 1986/87 on the site of the former Clarendon Hotel as a 19-storey RC frame building. After sustaining damage during the 2010/2011 Canterbury earthquakes the

building was scheduled for deconstruction.

The test specimens extracted from the Clarendon Tower

are similar in configuration and detailing to specimens previously tested at the University of Canterbury in the early 1990s (Restrepo-Posada 1993).

The extracted RC frames where repaired and then setup in a custom designed steel reaction frame to subject them to simulated seismic testing. Testing was completed at Atlas Steels warehouse in East Tamaki, Auckland'.

Regional Sports Facility, Wind Tunnel Analysis Process, Auckland, New Zealand

Compusoft Engineering were responsible for the management of wind tunnel tests performed by the University of Auckland on a 1/200 scale model of a proposed regional sports facility. Wind pressures as a result of winds from 36 angles on the roof were measured. Pressure was measured at approximately 256 locations over the upper and lower surface of the roof. The wind tunnel analysis procedure enabled the data recorded to be to processed into a format that could be used in a SAP 2000 software model of the structure.

The finite elements used to represent the canopy in SAP 2000 were used as a template to process the data. The SAP elements were then used to determine the normal vector and area of every element. It was then possible to calculate the x, y, and z components of the resultant pressure coefficient of each element multiplied by area.

Eden Park Rugby World Cup 2011 Temporary Seating Component Testing, University of Auckland, New Zealand

Compusoft Engineering was engaged to undertake the seismic analysis of the temporary stands that were installed at Eden Park, Auckland, to increase capacity for the 2011 Rugby World Cup.

During the course of this analysis work it became evident that validation of the strength of the system proposed for construction of these stands was required and that such validation could be achieved only through physical testing.

Testing was conducted on specimens consisting of two half members linked by a ringlock and short stub of column. The half members were attached to the ringlock using the wedge connection inherent to the system, while the other (cut) end of the half member was connected to the test machine via a pin inserted in a drilled hole.

All testing was conducted in the Civil Engineering Materials Laboratory at the University of Auckland. A 500 kN capacity displacement controlled MTS test machine was used to apply forces to the test specimens.

"Vector Curve" Precast Concrete Railway Sleepers Testing, University of Auckland, New Zealand

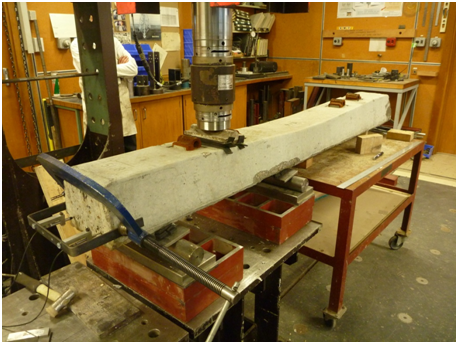

Compusoft Engineering was commissioned to organise, supervise, and report testing of three prestressed concrete railway sleepers.

Testing followed the procedure outlined in appendix K of AS 1085.14:2003, Railway Track Material – Prestressed Concrete Sleepers.

Testing was conducted during April 2012 at the University of Auckland Civil Materials Laboratory using an MTS testing machine with a load capacity of 500 kN.